Building custom garages or workshop sheds transforms unused backyard space into a tailored structure that enhances storage, workspace, and property value while complying with regulations and budget constraints. This guide delivers a clear roadmap for planning, foundation selection, framing, exterior finishes, interior systems, budgeting, and safety, helping homeowners navigate zoning laws, choose the right materials, and implement electrical and HVAC systems efficiently. We’ll cover essential planning steps, optimal foundation types, framing techniques, finishing options, interior customization, cost analysis, and safety practices to empower you with actionable insights for your custom backyard structure.

What Are the Essential Planning Steps for Building Custom Garages and Workshop Sheds?

Successful garage and shed projects begin with systematic planning that aligns site constraints, legal requirements, design goals, and customization options to ensure a durable, functional structure. Early-stage decisions about location, permits, and features lay the groundwork for a smooth build process.

How Do Zoning Laws and HOA Regulations Affect Backyard Structures?

Local zoning ordinances and HOA covenants govern setback distances, maximum square footage, height limits, and permitted uses for accessory structures. Reviewing municipal zoning maps and HOA design guidelines defines buildable area, roof pitch restrictions, and aesthetic standards. Understanding these regulations prevents costly revisions and ensures your custom backyard structure meets legal requirements while fitting neighborhood character.

International Code Council, Zoning Regulations for Accessory Structures (2023)

This research provides a framework for understanding the legal requirements for building custom garages and sheds.

What Building Permits Are Required for Garages and Sheds?

Securing the correct permits ensures structural safety and code compliance.

- Building Permit (applies to new construction and major renovations)

- Zoning Permit (verifies setbacks and land use)

- Electrical Permit (required for power installation)

- Plumbing Permit (needed for water supply and drainage)

Each permit involves submitting site plans, foundation details, structural drawings, and paying associated fees. Early permit acquisition averts work stoppages and helps finalize design dimensions before breaking ground.

Closing a building permit application unlocks detailed engineering requirements that guide foundation and framing specifications.

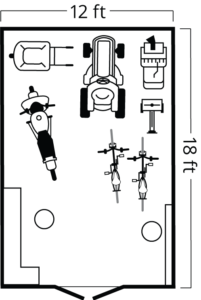

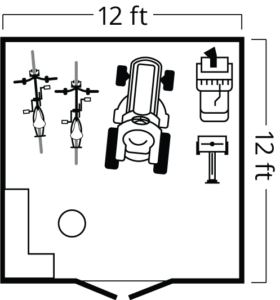

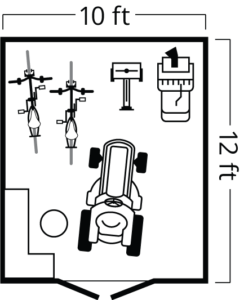

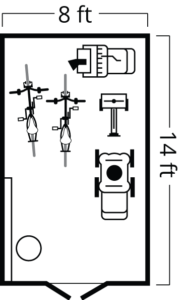

How to Choose the Best Site and Design Layout for Your Custom Structure?

Selecting a level, well-drained site free of overhead obstructions optimizes foundation performance and long-term durability. Consider solar orientation for workshop light, proximity to utilities for electrical and plumbing runs, and access routes for material delivery. Working with 3D design software or graph paper helps visualize space allocation for vehicle storage, workbenches, and storage bays. Integrating overhangs, loft storage, and clerestory windows enhances functionality and natural light.

Introducing the foundation stage, site preparation directly influences foundation selection and drainage planning under the structure.

What Are the Key Considerations for Customizing Your Garage or Workshop Shed?

Customization revolves around intended use, workflow efficiency, and special features.

- Usage Zoning: Define zones for vehicle parking, tool storage, and work areas to streamline movement.

- Insulation and Climate Control: Select wall and roof insulation levels for year-round comfort.

- Lighting and Ventilation: Plan for daylighting, task lights, and exhaust fans to maintain air quality.

- Smart Features: Integrate automated doors, security systems, and Wi-Fi access for convenience and safety.

Balancing these features with budget and permit constraints shapes a tailored structure that meets practical needs and personal preferences.

Which Foundation Types Are Best for Custom Garages and Workshop Sheds?

The foundation anchors load-bearing walls, resists moisture intrusion, and maintains level flooring. Proper foundation choice depends on soil conditions, structure weight, budget, and use.

What Are the Advantages of Concrete Slab Foundations?

Concrete slabs provide a durable, level floor that resists settling and supports heavy vehicles or equipment.

| Entity | Attribute | Value |

| Concrete Slab | Durability | High compressive strength withstands loads |

| Concrete Slab | Installation | Forms, reinforcement, pour, finish |

| Concrete Slab | Maintenance | Low—occasional crack sealing |

This slab foundation method creates a seamless floor ideal for auto garages and woodworking workshops, promoting easy cleaning and stable equipment setup.

When Should You Use Pier and Beam or Gravel Pad Foundations?

Pier and beam foundations elevate the structure, improving ventilation and access to utilities, while gravel pads simplify construction for small sheds on firm soil.

- Pier & Beam: Best for uneven terrain or flood-prone areas where crawl space access is needed.

- Gravel Pad: Suitable for lightweight sheds and temporary structures, offering quick installation.

Considering soil bearing capacity and moisture management helps determine the appropriate foundation type for your custom design.

How to Prepare Your Site for Foundation Installation?

- Excavate to the required depth, removing organic topsoil.

- Install drainage channels or gravel trenches to divert water away.

- Compact subgrade soil and add a gravel base layer for uniform support.

Proper preparation ensures foundation integrity, reducing the risk of settling or water damage as you proceed to framing.

Smooth site work leads directly into framing steps, ensuring your foundation aligns precisely with your structure’s layout.

How to Frame and Build the Structure of Your Custom Garage or Workshop Shed?

Framing establishes the skeleton that supports roofs, walls, and loads. Precision in framing assures straight walls and secure roof performance.

What Are the Best Wood Framing Techniques for Garages and Sheds?

Light-wood framing uses 2×4 or 2×6 studs spaced 16″ on center to form load-bearing walls.

- Double top plates for continuous support under roof loads

- Stud placements aligned over foundation anchors

- Sheathing installation improves lateral stability and resists wind loads

This method balances material efficiency and structural strength, promoting interoperability with common building codes.

How to Install Roof Trusses and Ensure Proper Support?

- Align trusses on wall plates at the manufacturer-specified spacing.

- Secure with hurricane ties or metal connectors to resist uplift.

- Brace trusses temporarily during installation until permanent lateral bracing is applied.

Well-supported roof trusses distribute loads uniformly, preventing sagging and ensuring long-term roof performance.

What Tools Are Essential for Framing and Construction?

- Circular saw and miter saw for accurate cuts

- Nail gun or framing gun for rapid fastening

- Level and laser level for plumb and square alignment

- Tape measure and chalk line for layout accuracy

- Safety gear (hard hat, safety glasses, hearing protection)

Equipping your team with proper tools enhances construction speed, accuracy, and safety, setting the stage for exterior finishes.

What Exterior Finishing Options Are Available for Garages and Workshop Sheds?

Exterior finishes protect structural elements and define aesthetic appeal. Material choices balance durability, maintenance, and cost.

Which Roofing Materials Are Most Durable and Cost-Effective?

| Entity | Attribute | Value |

| Asphalt Shingles | Cost | Low initial expense, moderate lifespan (15–25 years) |

| Metal Roofing | Durability | High—30+ years, fire-resistant |

| Synthetic Panels | Light weight | Low load on trusses, moderate cost |

Choosing the right roofing aligns long-term budget with local climate demands, ensuring leak-free, low-maintenance coverage.

What Are the Best Siding Options for Custom Backyard Structures?

Siding materials impact insulation, maintenance, and curb appeal:

- Wood (cedar, pine): Natural look, requires periodic staining

- Vinyl: Low-cost, low upkeep, limited styling

- Metal panels: Durable, modern aesthetic, higher cost

Selecting siding that complements your home’s style while preserving structural protection creates a cohesive property appearance.

How to Choose Garage Doors and Windows for Functionality and Style?

- Sectional roll-up doors provide space savings and insulation options.

- Sliding or barn-style doors deliver rustic appeal and manual operation.

- Double-pane windows with low-E glass enhance daylighting and thermal performance.

Integrating appropriate doors and window styles completes exterior finish design and improves the interior environment quality.

How to Install Interior Systems and Customize Your Workshop or Garage?

Interior systems like electrical, plumbing, and HVAC transform a bare shell into a functional workspace capable of supporting power tools, water usage, and climate control.

What Are the Basics of Electrical Wiring for Workshops and Garages?

Electrical wiring establishes safe power distribution for outlets, lighting, and tools.

- Install dedicated circuits for heavy loads (table saws, compressors).

- Ground fault circuit interrupters (GFCIs) protect outlets near water sources.

- Plan conduit runs and breaker panel capacity based on total load calculation.

Proper wiring ensures code compliance and the reliable operation of workshop machinery.

How to Plan Plumbing and HVAC for Backyard Structures?

Running plumbing requires pressure-rated PEX or copper lines from the main supply and proper venting for drains. HVAC solutions include mini-split systems for efficient heating and cooling without ductwork. Locating condensate drains and electrical connections in advance reduces retrofit costs and maximizes interior comfort.

Quality HVAC installation maintains stable temperatures for year-round workshop use and protects stored items from extreme heat or cold.

What Custom Features Enhance Workshop Functionality?

Integrating specialized features tailors your workshop to specific tasks:

- Soundproofing panels reduce noise from power tools.

- Dust-collection systems improve air quality and lower cleanup time.

- Adjustable workbenches and modular shelving optimize workflow.

- Smart lighting and automated controls enhance productivity.

These customizations elevate your workshop into a specialized environment that supports efficient, safe craftsmanship.

How Much Does It Cost to Build a Custom Garage or Workshop Shed?

Budgeting for a custom structure involves material, labor, permit, and tool expenditures. Accurate estimates guide financing decisions and scope adjustments.

What Are the Typical Material and Labor Costs?

| Entity | Attribute | Value |

| Materials | Cost per sq ft | $15–$25 (foundation to roof) |

| Labor | Installation | $20–$35 per sq ft |

| Permit Fees | Local average | $500–$2,000 |

A combined range of $10,000–$30,000 reflects design complexity, regional labor rates, and finish quality.

How Can DIY Building Save Money Compared to Hiring Professionals?

DIY construction can reduce labor costs by 30–50% when homeowners perform framing, siding, and basic electrical work. Savings emerge from purchasing materials at retail prices and scheduling work on personal timelines. However, specialized tasks such as structural engineering or complex HVAC installation may still require licensed contractors to maintain safety and code compliance.

Reducing hired-labor scope demands careful skill assessment and adherence to permits to avoid costly corrections.

What Tools and Equipment Should You Budget For?

- Power tools (saws, drills, nail guns) – $1,500–$3,000 total

- Scaffolding or ladders – $300–$800

- Concrete mixer (rental) – $100–$300 per day

- Safety gear (PPE, harnesses) – $200–$500

Allocating funds for quality tools enhances build efficiency and performance, delivering long-term value throughout construction and future projects.

What Safety Practices and Tools Are Essential for Building Garages and Workshop Sheds?

Adhering to safety protocols and equipping all workers with gear and training prevents accidents and ensures a secure jobsite.

What Safety Gear Is Required During Construction?

- Hard hats and safety glasses for impact protection

- Hearing protection when using loud power tools

- Cut-resistant gloves for handling lumber and metal

- Steel-toe boots for foot protection

Wearing mandated safety gear builds trust and reduces liability while fostering a professional work environment.

How to Use Power Tools Safely When Building Your Structure?

- Reading manufacturer’s instructions and observing maintenance schedules.

- Securing workpieces with clamps or vices before cutting.

- Checking blades and bits for sharpness and proper installation.

Implementing these practices prevents kickbacks, binding, and unintended cuts, leading to consistent build quality.

What Are the Best Practices to Ensure a Safe Building Site?

- Establish clearly marked walkways and tool storage areas.

- Maintain clean work surfaces, removing debris daily.

- Use proper fall protection when working at heights.

Keeping the site orderly and enforcing safety protocols supports uninterrupted progress and protects all participants.

Designing and constructing custom garages or workshops demands thorough planning, foundation expertise, precise framing, tailored finishes, interior systems integration, accurate budgeting, and stringent safety measures. By following these guidelines, you can create a durable, functional, and compliant backyard structure that enhances your living space and property value.

At Pleasant Run Structures, we believe safety is the cornerstone of every successful garage or workshop shed build. By pairing expert craftsmanship with strict safety protocols, we ensure your project is completed efficiently, securely, and to the highest standards. From providing proper gear and safe tool use to keeping the jobsite organized, our team takes every step to protect workers and deliver exceptional results. When you choose Pleasant Run Structures, you’re investing in a durable, well-designed space that enhances both your property and your peace of mind. Ready to start your project? Visit our website today to explore designs, learn more about our process, and request your free consultation.

Great For Yards

Great For Yards Great For Yards

Great For Yards Great For Yards

Great For Yards Great For Yards

Great For Yards